Research

The ability to effectively deliver new values to the market; innovation, is a challenge on global scale for companies today.

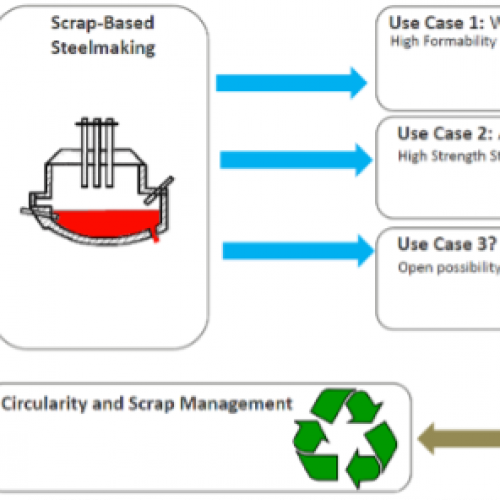

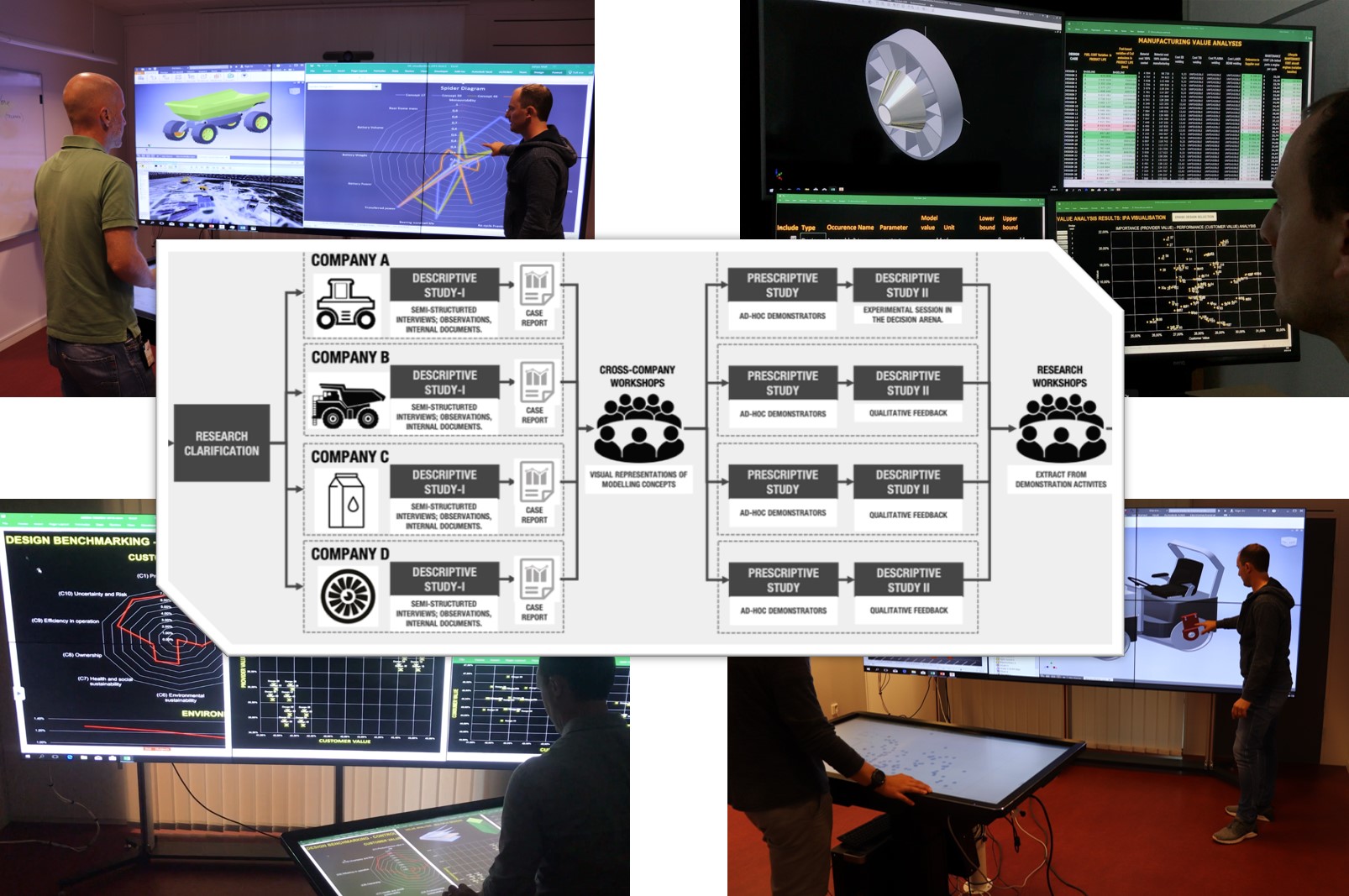

The research at PDRL aims at targeting early development stages of product (and production) development by use of a model based engineering approach with simulation at the core.

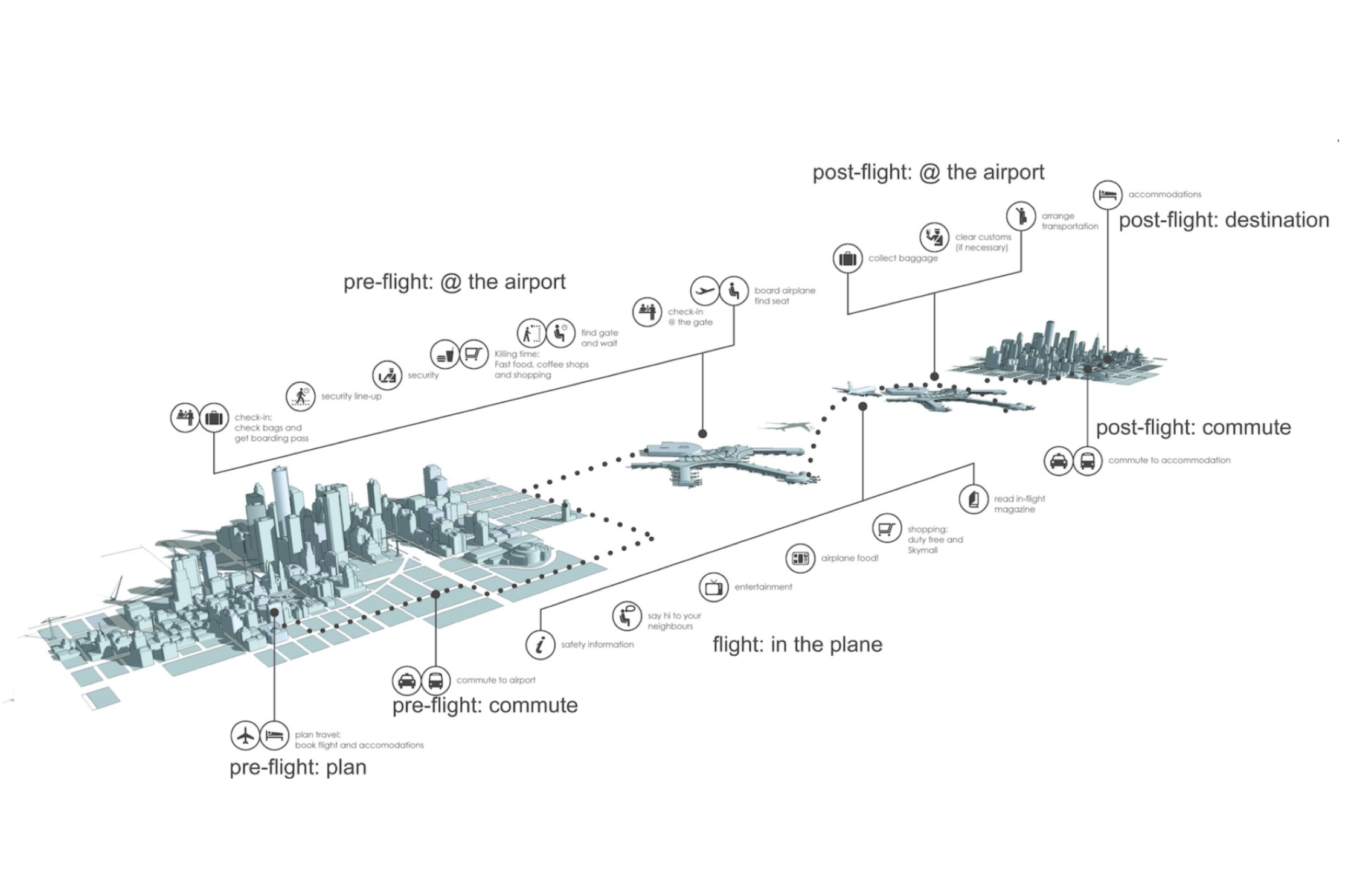

The research is particularly oriented towards early development, and questions of how to best identify, communicate, utilize, and re-use knowledge about, for example, user needs and product usage, are of high interest together with aspects of team based innovation, value creation and engineering optimisation.

Creating the ability to run simulation driven design of new sustainable solutions by using a model based approach is a key in order to support global product development where sustainable lifecycle solutions; product-service systems is the goal.

The applied research efforts provide new work procedures, methods and tools as well as new insights that support and enable product development improvements for our partners, while the research at the same time is disseminated in the proper academic channels to ensure quality control.

Below are our main research areas within mechanical engineering.

Latest Research Publications

AI-Driven Predictive Maintenance for Autonomous Vehicles for Product-Service System Development

Abstract The paper presents an Artificial Intelligence-driven approach to predictive maintenance for Product-Service System (PSS) development. This study focuses on…

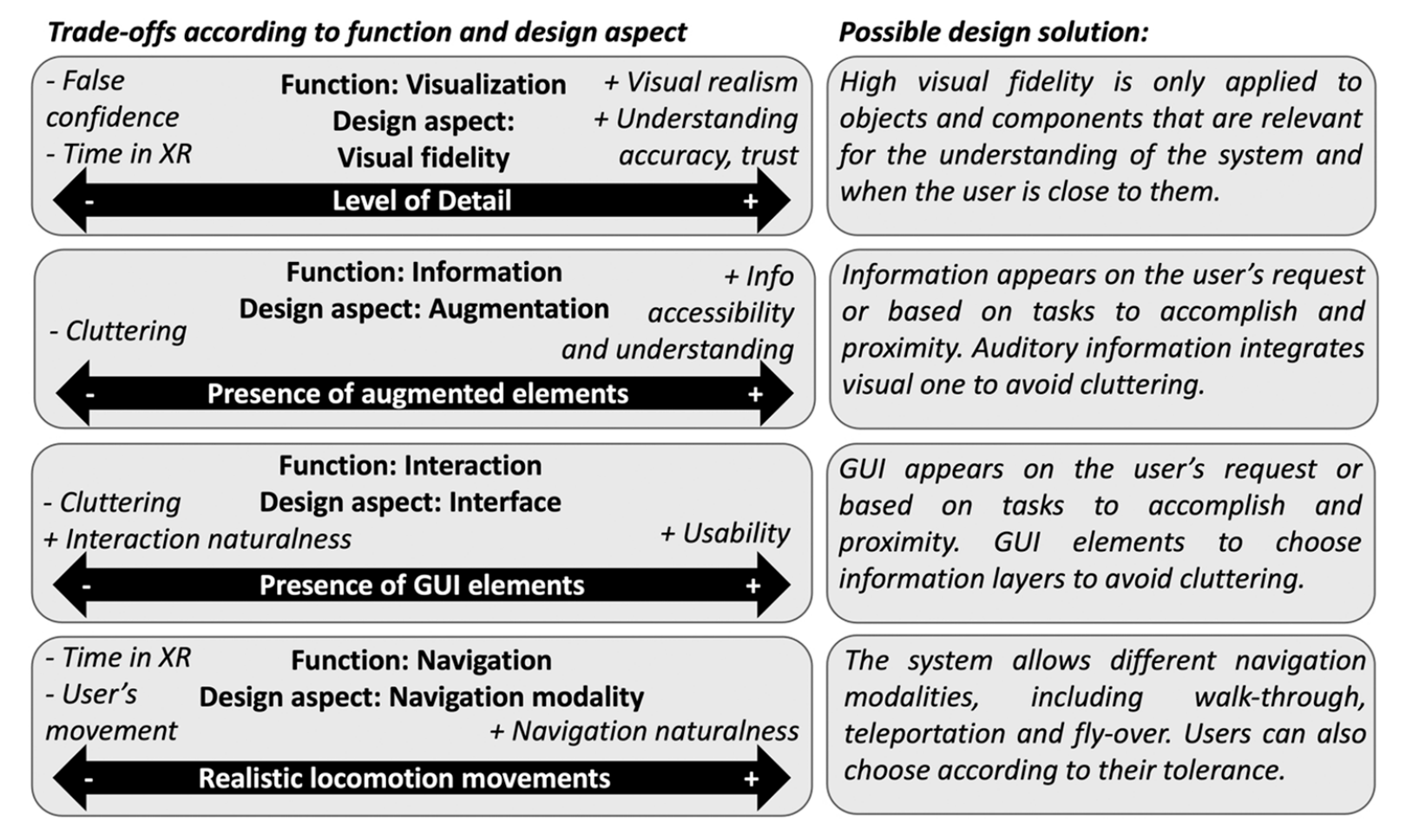

Extended realities and discrete events simulations: A systematic review to define design trade-offs and directions

Abstract Extended Reality (XR) technologies are increasingly popular to support the engagement of different audiences and stakeholders with Discrete Event…

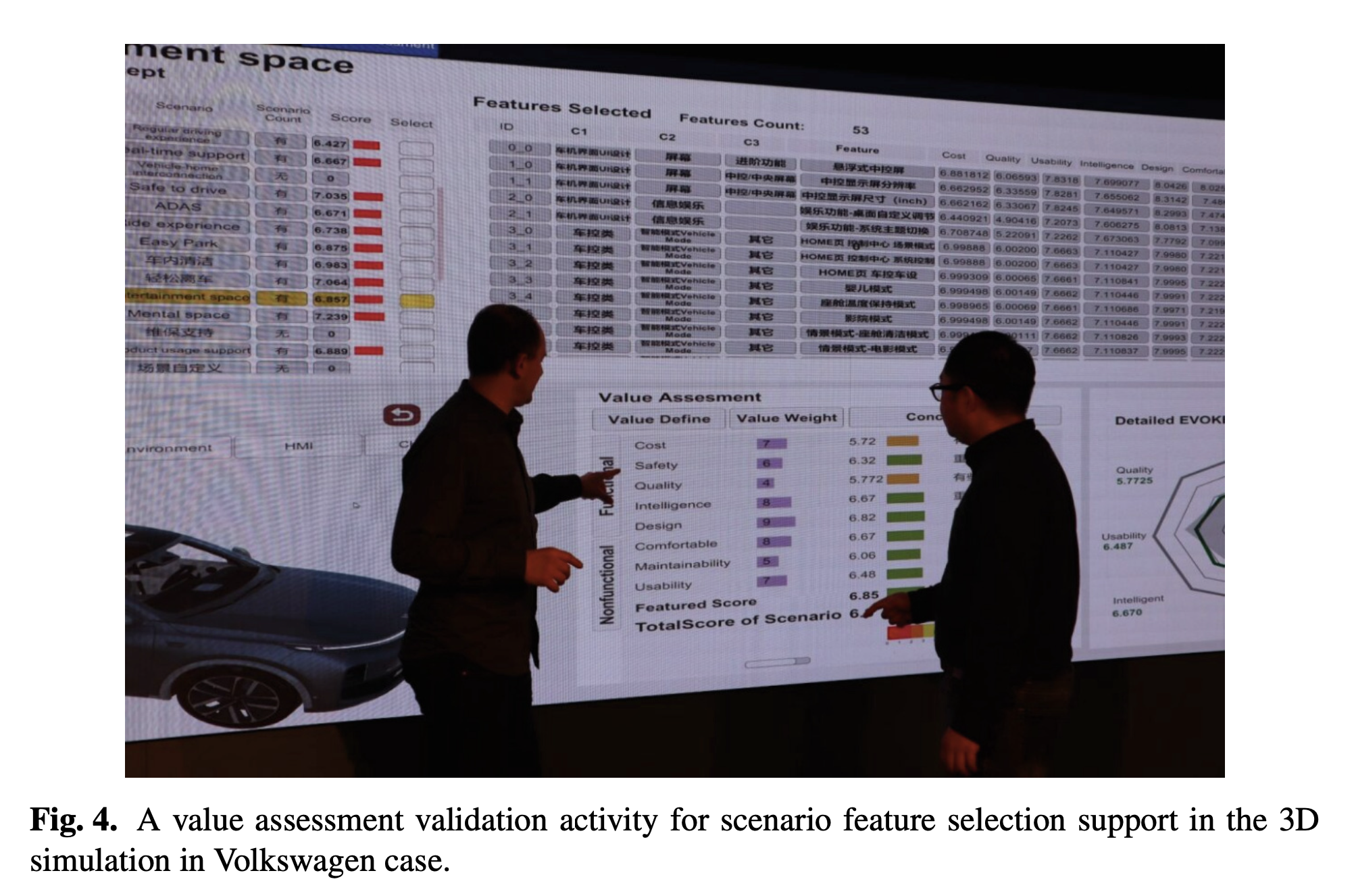

Utilizing Natural Language Processing for Enhancing Collaborative Value-Driven Design of Smart Product Service System: Smart E-Vehicle Application

Abstract Manufacturing companies are increasingly transitioning from a product-centric to a smart Product Service System (smart PSS) approach to enhance…

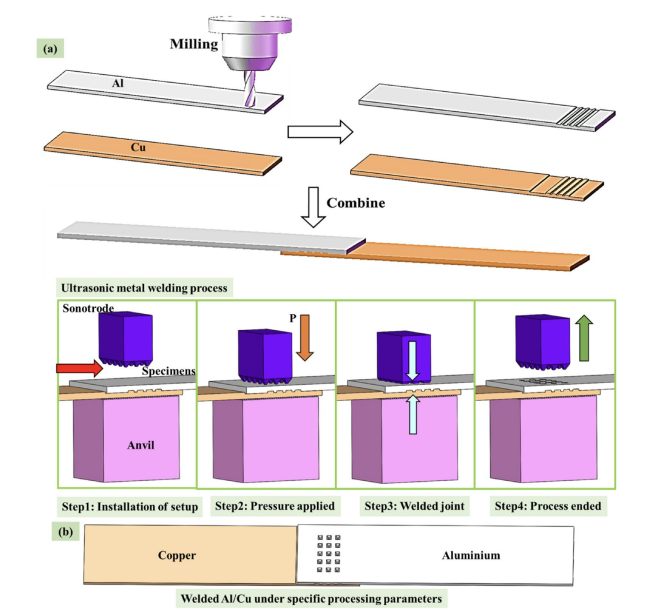

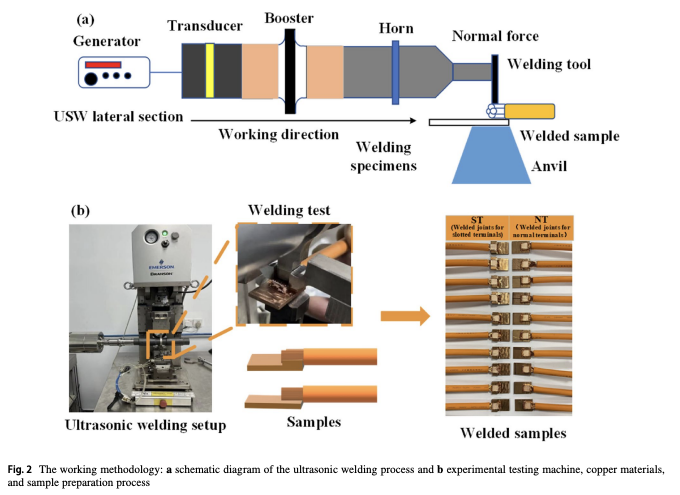

Surface-conformed approach for mechanical property analysis using ultrasonic welding of dissimilar metals

Abstract In this paper, dissimilar aluminum (Al) and copper (Cu) metals were joined together using ultrasonic metal welding (USMW), a…

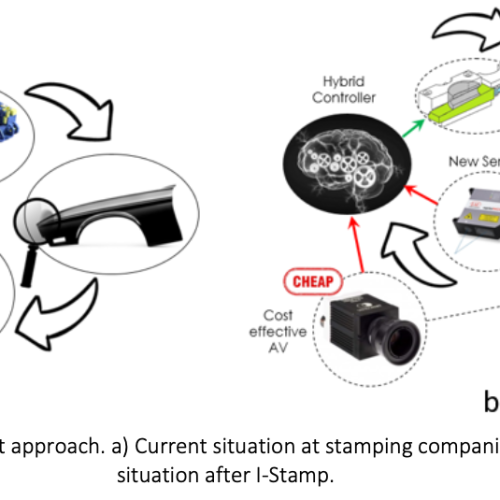

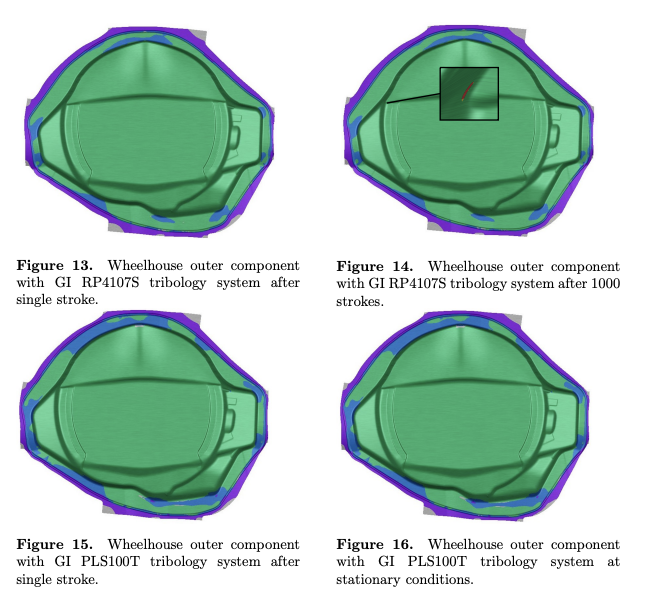

Investigation of Temperature Impact on Friction Conditions in Running Production of Automotive Body Components

Abstract During the running production of automotive body components drifts in theprocess window is seen causing problems with non-conforming parts.…

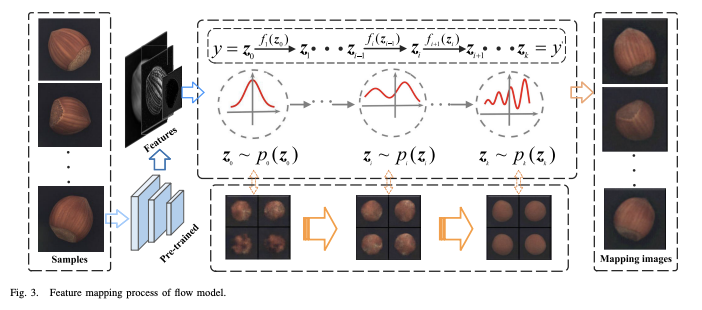

LightFlow: Lightweight unsupervised defect detection based on 2D Flow

Abstract In the industrial production process, unsupervised visual inspection methods have obvious advantages over supervised visual inspection methods due to…

LAD-Net: A lightweight welding defect surface non-destructive detection algorithm based on the attention mechanism

Abstract Ultrasound welding technology is widely applied in the field of industrial manufacturing. In complex working conditions, various factors such…

Low-temperature mechanical properties of slotted and normal terminals using ultrasonic wire harness welding

Abstract The ultrasonic metal welding technology is widely promoted as a new connection approach in the field of current energy…

All publications here

Research Projects

Contribution to the Sustainable Development Goals

The Sustainable Development Goals are a call for action by all countries – poor, rich and middle-income – to promote prosperity while protecting the planet. We contribute to the below goals, where #9 and #12 are our high impact goals. Here is our breakdown of the PDRL contributions.